I'm finally putting my PM66 table saw back together and am looking at the Baldor 3HP Single phase motor but am not quite sure about hooking juice up to it. Essentially none of the label is intact but I think it should be fairly straight forward. I can always load it in the back of the MINI and take to the shop that rebuilt it for me to see how to hook it up if I have to.

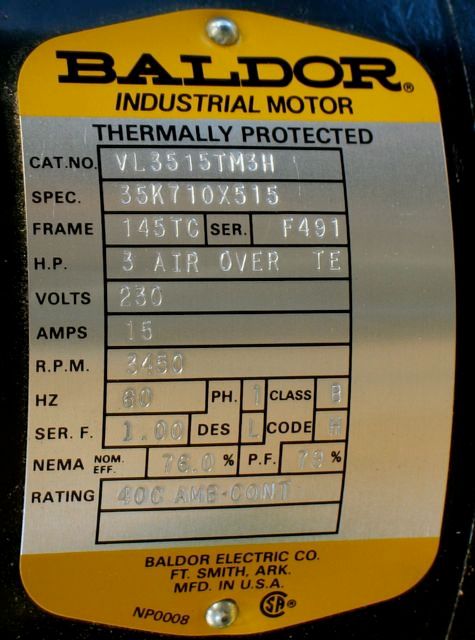

Here's what I can see on the motor tag -

Cat. VL3515TM3H

Spec. 35K710X515

Frame 145TC Serial F597

![]()

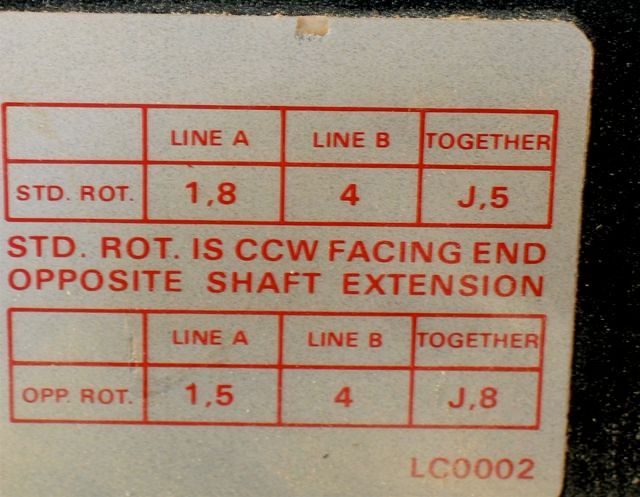

Wiring

Single white wire says '4'

White/Black tied together says '8' on the white wire

Two with wire nut were that way when I got it back from rebuild shop (and was probably that way when I took it to them)

Green, obviously ground

![]()

So I'm thinking that if I hook power to the two obvious wires and rotation is correct then I'm home free. If rotation is wrong then I take the black off the '8' wire and put it on the '4' wire.

Is anyone confident enough to advise me on this or do you have a good clear photo of the wiring diagram off of your PM66 with the same motor?

Thanks!

David

Here's what I can see on the motor tag -

Cat. VL3515TM3H

Spec. 35K710X515

Frame 145TC Serial F597

Wiring

Single white wire says '4'

White/Black tied together says '8' on the white wire

Two with wire nut were that way when I got it back from rebuild shop (and was probably that way when I took it to them)

Green, obviously ground

So I'm thinking that if I hook power to the two obvious wires and rotation is correct then I'm home free. If rotation is wrong then I take the black off the '8' wire and put it on the '4' wire.

Is anyone confident enough to advise me on this or do you have a good clear photo of the wiring diagram off of your PM66 with the same motor?

Thanks!

David